Aug 13,2024

Spring machines have been pivotal in driving industrial advancements and shaping modern engineering, playing a crucial role in the evolution of manufacturing processes and technological innovation. The development of these machines reflects broader trends in industrial automation and precision engineering, with each advancement contributing to increased efficiency, versatility, and quality in production. From their early manual counterparts to today’s sophisticated CNC models, spring machines have continually pushed the boundaries of what is possible in manufacturing.

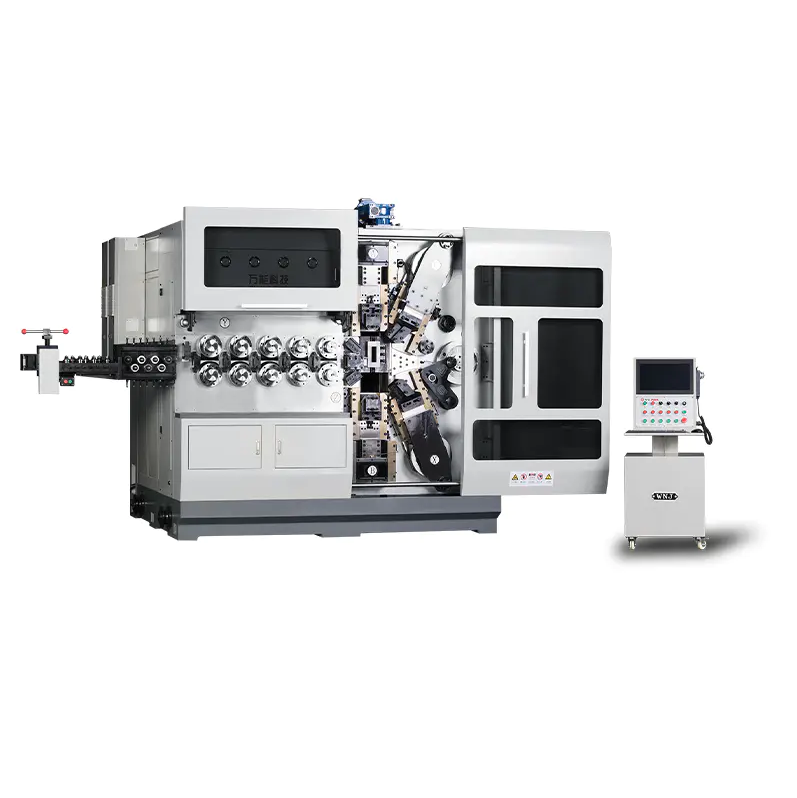

Historically, the advent of spring coiling machines marked a significant leap from manual production methods to mechanized processes. Early machines, though rudimentary compared to today's standards, introduced the ability to produce springs with greater consistency and accuracy than hand-crafted methods. This transition allowed industries to meet the growing demands for precision components driven by the rapid industrialization of the late 19th and early 20th centuries. As manufacturing processes evolved, so too did the technology behind spring machines, incorporating advancements such as automated controls, multi-axis systems, and computer numerical control (CNC).

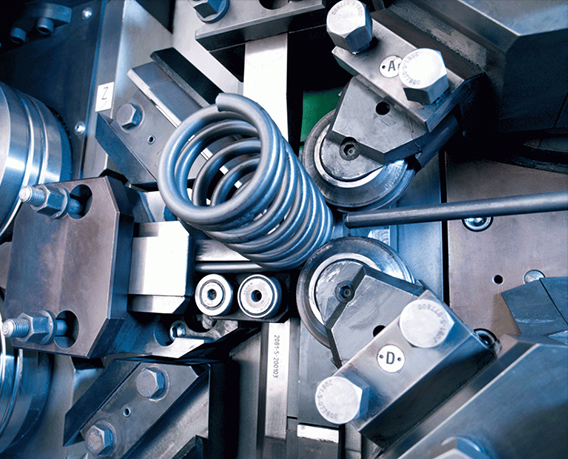

The impact of these technological advancements on modern engineering is profound. Contemporary high-end spring coiling machines, such as those equipped with five-axis control and automatic programming, offer unparalleled precision and flexibility. These machines can produce a wide variety of springs with intricate designs and tight tolerances, which are essential for high-performance applications in industries such as aerospace, automotive, and electronics. The ability to perform complex cutting methods and handle diverse wire materials has expanded the possibilities for engineering applications, allowing for innovations in product design and functionality.

Furthermore, the efficiency gains from advanced spring machines translate into significant commercial benefits. The reduction in production time, lower waste rates, and the ability to handle larger volumes contribute to a more streamlined manufacturing process. This efficiency not only lowers production costs but also enhances a company’s ability to respond to market demands swiftly. The reliable and consistent quality of springs produced by modern machines supports the development of high-tech products and systems, which are increasingly integral to modern engineering solutions.

In addition to their direct impact on manufacturing, spring machines have also influenced broader engineering practices. The precision and reliability demanded by high-end spring machines have driven advancements in related technologies, such as robotics, automation, and materials science. As industries continue to innovate, the role of spring machines remains central to ensuring that new products and systems perform reliably and efficiently.

Spring machines have played a transformative role in industrial advancements and modern engineering. Their evolution from simple mechanical devices to advanced CNC systems reflects the broader trends of automation and precision in manufacturing. By enabling the production of high-quality, precise components, these machines have not only enhanced manufacturing efficiency but also supported the development of cutting-edge technologies and engineering solutions. As the demand for increasingly sophisticated and reliable components continues to grow, the role of spring machines in driving industrial and engineering progress remains as vital as ever.

English

English 中文简体

中文简体 Español

Español русский

русский

Stock Code: 000906

Stock Code: 000906